Streamlined processes & manufacture capabilities.

CURRENT PROJECTS

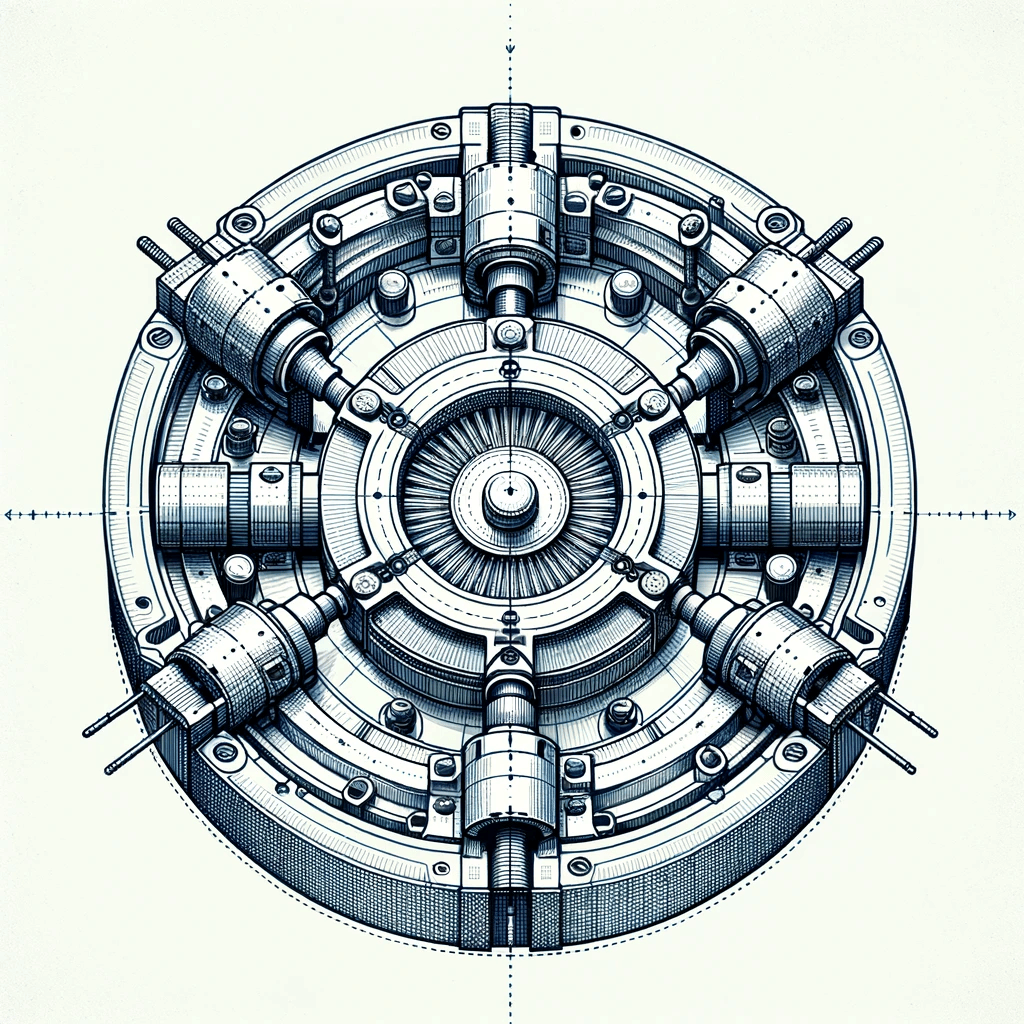

PSCB MK-0 & MK.1

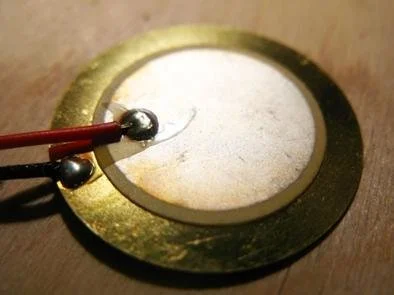

The basic Principle proven last year and the MK-0 Showcase Prototype nearing completion in Q1, we are looking at realizing the initial MVP 9V+ Concept. CAD work has been completed by our Design Team and is currently being reviewed before we dive into scaling.

PAMMO COre MK-X

The mechanical and material properties of our initial PSCB Design make it a solid basis for our future vision of a peaceful world while addressing our fears of robots and the irrational looming of technocracy, -our Piezoelectric-Self-Charging-Battery based Active Machine Mitigation Ordinance saves.

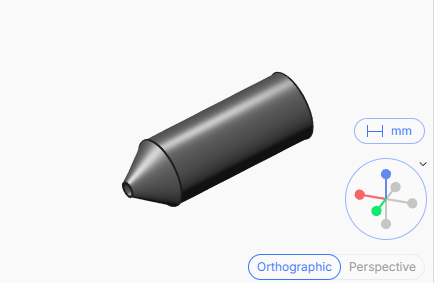

Skill EXAMPLE

CODE TO CAD

With our proprietary approach to part creation, no idea is too abstract to illustrate. Using state-of-the-art modeling tools, calculations, and design converge. With more than 35 Proprietary Parts created and many more in the works, our toolshed constantly grows. Give us the word, and we will give you the CAD. Although we are focused on providing services in-house first, exciting and challenging projects make us grow.

-

Working with state-of-the-art tools of of our trusted provider Cyberlink, we are up to the task of illustrating even the most complex ideas. Further our reliance on our Inglewood, CA-based CAD and Software Supplier: The ZOO Corporation. (Not the one in Japan.)

-

With our insistence on the extraordinary, it is important to strive for the delivery of something unique. However, it’s important to be humble, therefore we must note that the beauty of convergence is merely discovered- never created.

-

As we are establishing a manufacturing standard with Start-Up uncommon ambitions for a swift ISO Certifications, we aim to be ISO 9001 Certified in no time - with many more in application.

Suppliers

-

At KCM, we collaborate with top-tier suppliers to source advanced materials tailored for our cutting-edge technologies. From piezoelectric ceramics to innovative composites, every material we use is selected for its performance, sustainability, and alignment with our technological goals.

-

Quality is the cornerstone of our production process. We adhere to stringent testing protocols and partner with suppliers who share our commitment to excellence, ensuring every component meets the highest standards of reliability and precision.

-

With a focus on ethical and sustainable sourcing, KCM maintains a transparent supply chain. By working closely with suppliers across the globe, we ensure that our materials are responsibly procured, fostering innovation without compromising integrity.

Integration

-

Seamlessly blending form and function, our integration process ensures that every design component fits harmoniously into the bigger picture. Whether it's a prototype or a production-ready system, our multidisciplinary approach bridges creativity with technical expertise.

-

Leveraging insights from our consulting division, we provide tailored solutions to ensure the smooth integration of new technologies. By aligning our needs with our innovative strategies, we optimize processes and outcomes across industries.

-

Our research team plays a pivotal role in integration, combining cutting-edge discoveries with real-world applications. This synergy enables us to refine and enhance our production capabilities, driving both innovation and efficiency.

Partners

-

KCM actively engages with public institutions and government bodies to drive impactful collaborations. From research grants to partnerships like the Faraday Battery Challenge, we align our innovations with public initiatives to maximize societal benefits. Just recently we have received our UEID from the US-Government.

-

Our partnerships with private enterprises are built on trust, expertise, and shared vision. By working alongside industry leaders, we co-create solutions that push the boundaries of technology and open new markets for growth.

-

Bridging the gap between public and private sectors, KCM thrives on hybrid partnerships that combine resources, expertise, and reach. These collaborations empower us to deliver scalable and sustainable solutions, from groundbreaking prototypes to full-scale production.'